Small to medium-sized companies must continuously improve or die. Approximately 84% of all American companies have less than 50 employees. There must be more focus on helping the entrepreneurial organizations that are core to local economies. This article offers a model for smaller businesses to implement a quality program. Smaller companies may not realize the huge returns of a large company, but that does not reduce the impact of the return on investment.

Grace Duffy, President, Management & Performance Systems

Grace will be speaking at IRM UK’s Business Analysis Conference Europe 23-25 September 2019, London; on the subject, “A Systems View of Modular Kaizen and the OODA Loop“

Starting with Quality

Every company must satisfy customers, stakeholders, and employees. This is survival. Day-to-day details often divert attention from what is good for the company as a whole. Conflicts in priorities and contention for resources combine to form a huge barrier to organizational excellence. Smaller businesses have a narrower buffer to shelter us from error and waste.

In a small business, quality planning and business planning are synonymous. The best time to start a quality program is during the initial planning for the business. At business start up, designing quality into product and service delivery is essential. Integrating quality into an existing company culture is more difficult, but no less critical.

Smaller businesses have certain advantages over large business:

• Small business can move faster; innovative ideas are approved and developed much faster.

• Communication channels are shorter and simpler.

• Fewer bureaucratic procedures must be overcome in getting ideas to market.

• Company members acquire decision-making skills faster by exercising authority granted them.

• Members tend to form a closer-knit effective work team.

These advantages are an important springboard for management in starting a quality program.

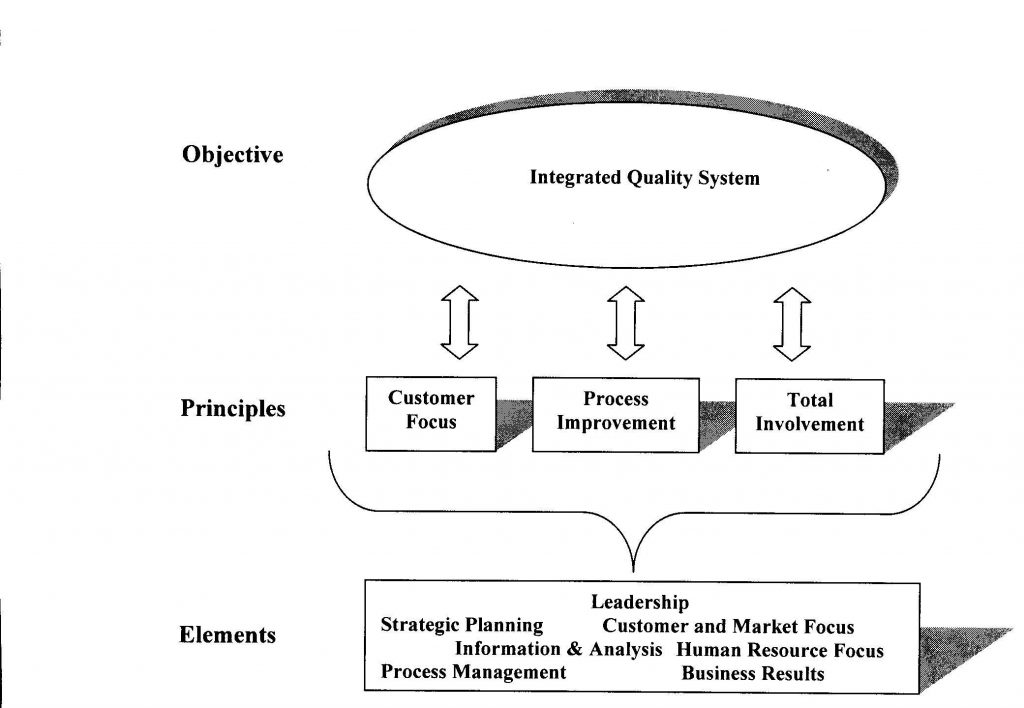

Figure 1 illustrates the integration of elements of a successful business into three principles supporting a complete quality system . All members of the business must be involved in the maintenance and improvement of the organization.

A truly integrated quality system is based on three principles: customer focus, process improvement, and total involvement. Customer focus encompasses both the external and internal customer’s needs. Process improvement is the life-blood of an organization wishing to sustain growth. Total involvement is the vehicle through which the company realizes the daily activities that accomplish the first two principles.

The elements in figure 1 are taken from the Malcolm Baldrige Performance Excellence Criteria. Small to medium-sized businesses compete along with Fortune 100 businesses for recognition under these criteria. Other models are successful in helping small business leaders segment their processes into measurable and stable components. The Baldrige website offers a free tool to assist companies of any size assess their initial quality position. This assessment can be downloaded in PDF format at www.baldrige.nist.gov. One of the first things managers are instructed to do during business planning activities is a SWOT (strengths, weaknesses, opportunities, and threats) analysis. The Baldrige self-assessment is an excellent complement to the traditional SWOT exercise.

Successful Process Design

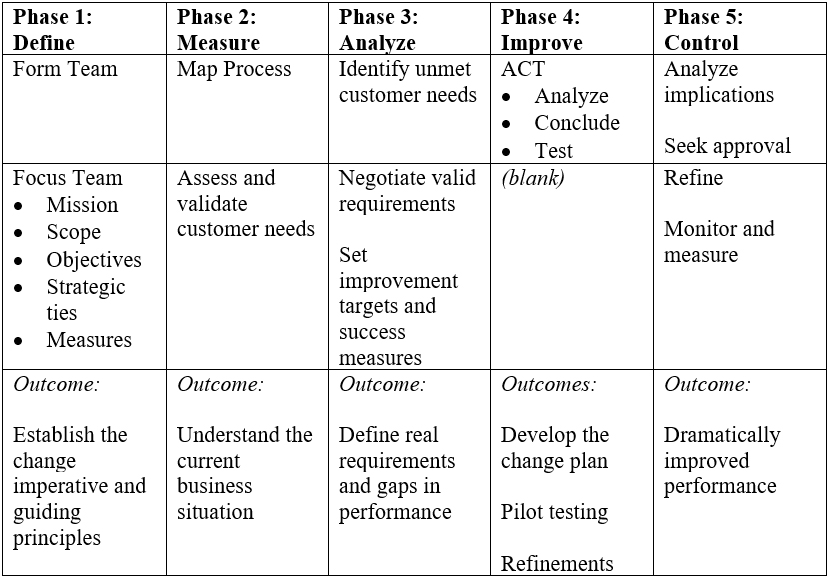

Figure 2 illustrates a five-phase methodology supporting a systematic process of improving how work is done in organizations. This methodology supports the whole company; not a subset of activities labeled “quality”. Quality must be integrated into every phase of the business to be totally effective.

The methodology asks two key questions at every phase:

- Does the process under study support the organization’s strategic mission?

- Is the process under study necessary to meet the demands of our customers?

The Baldrige model can be easily fed into this methodology. Each element of the quality program becomes a mega-process for design under the Change Implementation methodology.

The Baldrige Performance Excellence elements are:

• Leadership

• Strategic Planning

• Customer and Market Focus

• Information & Analysis

• Human Resource Focus

• Process Management

• Business Results

Using the phases identified in figure 2, the company leaders and workers assign teams to address each element in turn. Senior leadership must be active in the define phase of each element. In many companies with fewer than 50 employees, the leadership team will be involved in all activities of implementing the quality system. As identified in figure 1, total involvement is a critical principle of an effective quality system.

Senior management usually undertakes this focus step as the result of an organizational assessment and thorough data analysis, such as the Baldrige self-assessment or SWOT discussed earlier. The owners or executives sponsor teams of leaders and employees in designing the seven elements. They focus organizational resources on improving the processes selected. In addition, as teams meet for the first time, they must focus on management’s requirements of their work together.

Two major activities are required during the first phase of instituting a quality program:

- Identify the scope of its proposed work and,

- Document its agreements with the executive sponsor.

The executive sponsor reviews the original process design team assumptions, thus ensuring alignment of mission, scope, objectives, ties with strategy, and measures of success.

The second phase is the measure phase. Here the real work begins. The leadership team starts by gathering baseline data along two dimensions:

- Process capabilities

- Customer needs.

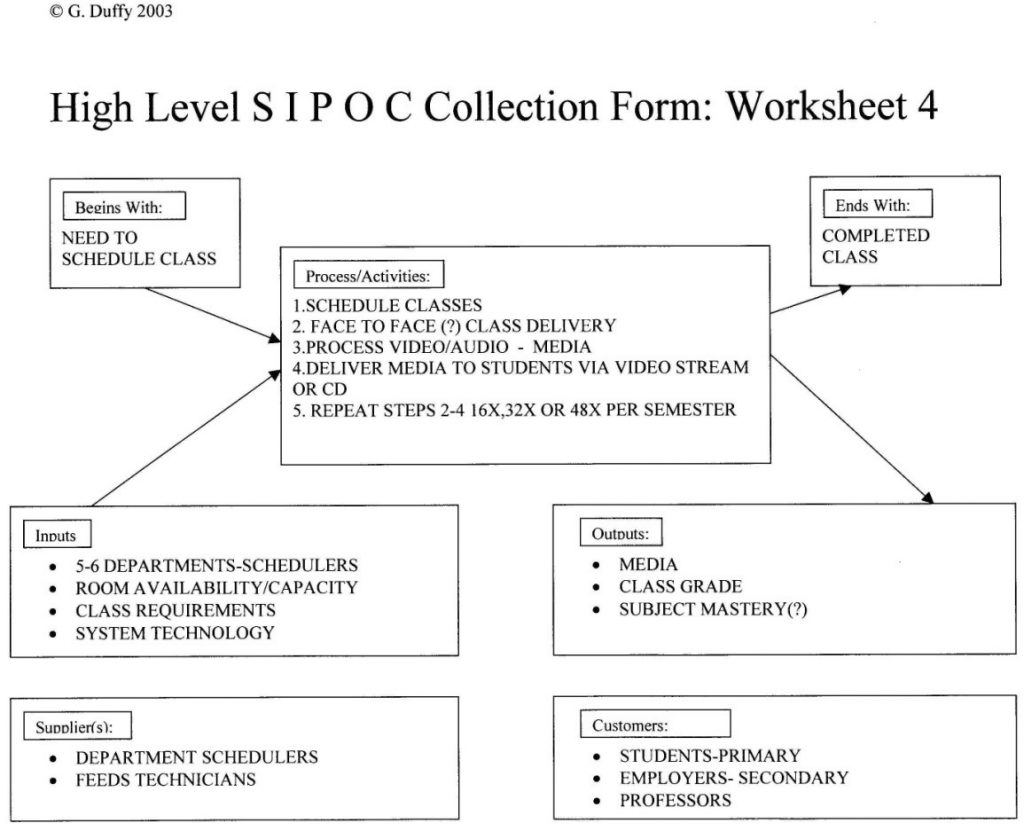

Determining process capabilities (what the company can do or deliver) involves mapping the flow of activities as they currently occur and measuring the input, output, and value-added of these activities, separately and in total. Figure 3 is an example of a completed SIPOC (Supplier, Input, Process, Output, Customer) worksheet for the distribution process of a distance-learning program at a public university. This chart is useful for identifying the scope of the element being integrated into the quality program. If the company is working on the Strategic Planning element, they would identify what Strategic Planning starts with, what activities it involves and what the Strategic Planning element ends with in their company. The lower part of the worksheet helps the company identify inputs and outputs of the Strategic Planning element, along with the suppliers and customers of that process.

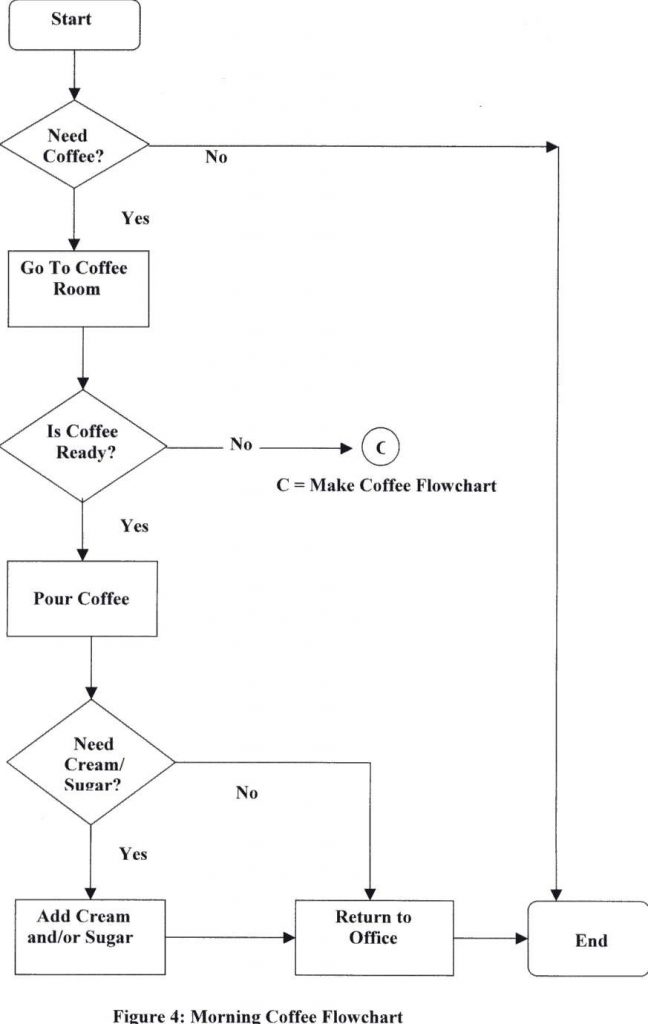

As the team develops its flowchart of current state, many times they find unnecessary work being performed or reports developed, and eliminate them during this step. This is a dynamic process. Improvement activities need not wait until the end of the process. The smaller business is more flexible in taking action with less bureaucracy than the larger organization. Figure 4 is an example of a flowchart for getting coffee.[i] A team familiar with the process being charted best develops flowcharts. It is common for the team to immediately find opportunities for improvement during the charting activity. See the sidebar accompanying this article for references to this and other basic quality tools.

Assessing customer needs is critical to measuring the success of a process. This component of assessment involves identifying the customers of the process, documenting what the team knows these customers currently need and might expect in the future, and planning how to close any gaps in knowledge and understanding.

These two dimensions of assessment should be performed concurrently to align process capabilities with customer needs. There are two risks in aligning these two dimensions. One is in missing performance gaps that occur when a process is not meeting customer needs. The other is missing growth opportunities or risks critical to the business. These occur when a process delivers beyond what customers need. A company should leverage this second situation. When a process delivers in anticipation of true, future expectations, this performance can be a company’s competitive advantage.

The measurement phase is concerned with performance on three dimensions:

- Process time (cycle time or throughput)

- Costs (fixed and variable)

- Rework and defects (product or service quality)

If the process performs well on all three dimensions and is built to the appropriate customer requirements, customer satisfaction should follow. Realize, however, that these three dimensions are internal measures for implementing the quality program. Customers don’t care what it costs the company to get work done. Customers care about product or service outputs and their interface with the people who deliver them.

The next phase is critical to the senior management. Leadership in the company must pause long enough to verify that all stakeholders have been drawn into the quality program design as process partners.

Critical to an understanding of process partnership is negotiating the validity of customers’ needs. Needs are not valid requirements until the company is committed to fulfilling them. This analysis involves discussion, joint ownership, and collaborative problem solving. Look for opportunities to give and take during this phase. Negotiation means being flexible; looking for the good of the whole business system. This phase usually concludes with a reconsideration of goals.

The reconsideration in the previous phase leads to phase four: improve. The company makes decisions about how the process might work better. This often manifests itself in a series of educated guesses upon which leadership establishes pilot improvements. The guesses are called educated because they are based on leadership’s careful analyses of valid data.

This phase offers a natural synergy of getting the right people in the room. Small business has a better ability to congregate those most knowledgeable about a particular work process. They explore opportunities for future savings, such as lowered costs, reduced process time, and improved output or service quality. By this time, company leadership has started to draw conclusions about where they can change things to meet stated customer needs.

Phase four suggests three steps to better manage unintended consequences of change that invariably pop up during implementation:

- Analyze the process to look for the root causes or drivers of performance gaps.

- Draw conclusions about what change will close these gaps.

- Test conclusions about whether the right improvements are identified and whether they go far enough.

This three-step cycle is easy to implement, since every time a team begins describing a current process, they usually end up analyzing it for suggested improvements.

The last phase finally gets us to control. By now, the leadership team should be ready to test and finalize new standards for how work flows through the system as a whole. Identifying indicators of progress and success are an important part of this last quality program implementation phase.

Indicators of Success

To be successful, any company must measure and report its performance on a routine basis. When designed and implemented effectively, performance measurement provides the following benefits:[i]

- Supports the organization’s strategic plan by providing management with tangible indicators and goals relevant to daily activities.

- Provides executives with sufficient and timely information regarding the effectiveness of operations before significant financial impacts are experienced.

- Creates a work environment that supports and rewards cooperation among key functional areas to attain desired results.

- Drives change by focusing resources and shaping behaviors toward specific, tangible results.

- Establishes a mechanism for assigning and enforcing accountability, as well as for recognizing and rewarding outstanding performance.

The target for measurement is processes and functions that, when performed and managed effectively, play a critical role in driving positive financial results (and visa versa).

The key aspects of defining effective measures are:

- Identifying those areas of business that play a critical role in your success (financial, satisfaction, operations, or other focus area).

- Participation of departmental and functional managers that control key areas in the overall measurement design and implementation efforts.

Involve all levels of the organization to define the critical success metrics that measure progress and results associated with each process. While most managers have a solid understanding of what their department and staff is responsible for, they are so close to the activity their focus becomes too micro in nature.

Some points for consideration:

- It is easier to edit than to create. Where possible, use metrics already available and commonly used to track performance in your industry.

- Success metrics between departments should be complementary. Metrics are most likely interdependent at some level.

- Success metrics must be relevant to the particular function to which they are being applied.

- Success metrics should be defined in terms that continue to be relevant as the business evolves over time.

- Success metrics should be relatively easy to calculate and understand. To be effective, this information must be understood from the boardroom to the break room.

- Not all effective measures are quantitative. Many human areas of business lend themselves to measures related to timeframes, frequency of occurrence, or other qualitative parameters.

The Human Element

So how do we transform all this process integration into a highly effective quality system? We use the resources available to us. The human resources of your company are tremendously valuable if you maintain the environment in which they can be successful.

Involve all levels of the organization in design and implementation of the new quality program. Use the “top to bottom and back to the top” concept of establishing a senior management vision, sharing it with the whole organization, and listening to the ideas of those impacted by the changes.

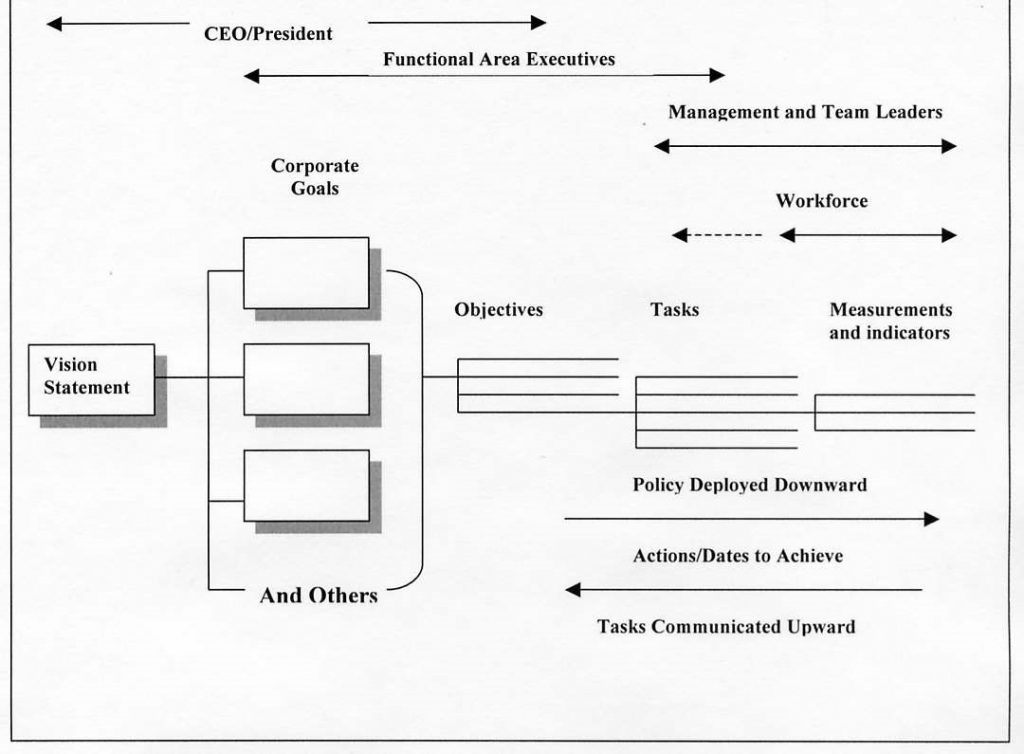

Figure 5 is a graphic representation of the levels of involvement necessary for implementing a quality program into a business of any size.[ii] A small to medium-sized business has the benefit of less complexity and clearer channels of communication.

Executive management has the responsibility of strategic planning, SWOT analysis, customer and market research and the development of a company vision. Once senior management has identified the general direction of the company, functional managers are involved to take the vision to the tactical level. Goals are identified in support of the company as a whole and in support of the functions that comprise the total enterprise.

Functional areas work with middle and first-line managers to identify specific tactical objectives. First-line managers, team leaders and the general workforce address each of these objectives in terms of specific outputs to meet customer needs.

Keeping it Current

Senior management must frequently review the anticipated effects of proposed changes on the people and systems of the organization. How might these changes affect the competencies of those who do the work? How might these changes affect the gathering and use of information needed to get the work done? What reward mechanisms exist to encourage continuous application of the new and improved quality processes? The company owners must take another systems view of the whole. Successful implementation of an integrated quality program is an iterative process.

It is senior management’s responsibility to consider recommendations of the teams in the context of each other. Remember, changes to one process are not made in a vacuum; all processes must be aligned so the entire system functions at an optimal level. This process adapts to the industry since it is focused on improving processes, which every industry has as its core for delivering its products or services to its customers.

Implementing a quality program is not a one-way process. The drill-down sequence shown in figure 5 must have a strong feedback element. Policy deployment is shown moving downward in the organization. Action and finite completion dates must be reported back up the organization. Tasks that require additional resources or escalation also flow back up the management ladder. Proper use of team dynamics encourages a strong horizontal and vertical communication web within the organization.

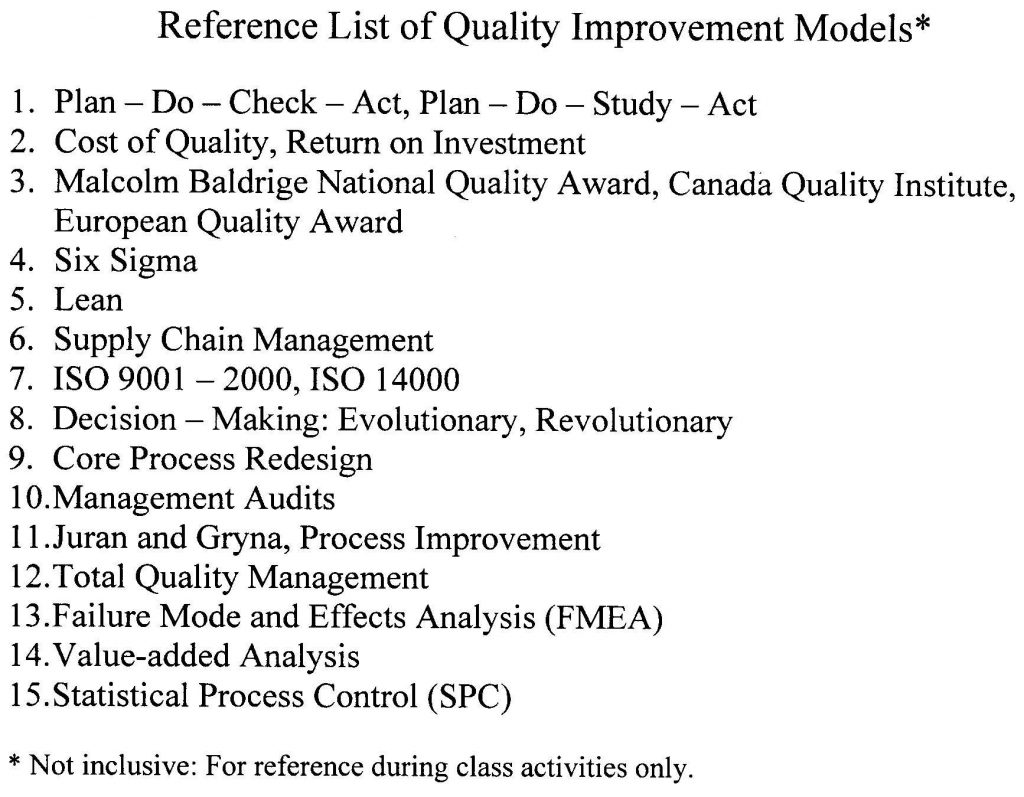

The Change Management model is a flexible sequence that supports any number of quality program structures. The author uses the Malcolm Baldrige Performance Excellence model because it is used so frequently by businesses of all sizes. Another model commonly used is the ISO 9001 – 2008 criteria. Local quality consultants are usually available to assist with either of these options. Table 1 offers a number of models further described in a book co-edited by the author.[i] Other references are suggested in the sidebar accompanying this article.

Integrating a quality program into your business is not a one-time activity. Once the program is implemented and tested, it is imperative that a continuous measurement and improvement cycle be instituted to keep the program effective. The effort to implement quality into all areas of the company is no small task. The benefits and results are well worth the effort, however.

Grace Duffy has over 40 years’ experience in successful business and process management in corporate, government, education, and healthcare. Grace uses her experience as President, CEO and senior manager to help organizations improve. She has authored 13 texts, additional book chapters, and many articles on quality, leadership and organizational performance. She is a frequent speaker and trainer. Grace holds an MBA from Georgia State University. She is an ASQ CMQ/OE, CQIA, SSGB, and CQA. Grace is a LSS Master Black Belt, ASQ Fellow and Distinguished Service Medalist. Grace is the 2014 Quality Magazine Quality Person of the year and the 2016 recipient of the Asia-Pacific Quality Organization Milflora M. Gatchalian International Woman in Quality Medal.

Copyright Grace Duffy, President, Management & Performance Systems

iKuriloff, Arthur H., Hemphill, Jr. John M.; Cloud, Douglas, Starting and Managing the Small Business; 3rd ed., McGraw-Hill, 1993

iiTenner, Arthur R. and Detoro, Irving J.; Total Quality Management: Three Steps to Continuous Improvement, Addison Wesley, 1992

iiiBeecroft, G. Dennis, Duffy, Grace L., Moran, John W.; The Executive Guide to Improvement and Change, Quality Press, 2003

ivEvans, James R., Lindsay, William, M.; The Management and Control of Quality, 5th ed, Southwestern, 2003.

vSee endnote # 3, Waks, Richard A. and Moran, John W., Chapter 6.

Ibid

viBauer, John B., Duffy, Grace L., Westcott, Russell T., The Quality Improvement Handbook, Quality Press, 2002

viiSee endnote #3, Sharlow, Kevin, Chapter 14.

viiiJablonski, Joseph R.; Implementing TQM, Pfeiffer & Company, 1992.

ixSee endnote # 3.

xSee endnote # 3.

Comments

Thank you to each of the professionals who have responded to this paper. Although the paper approaches the perspective of a small business, it is simply a matter of scale for implementing a quality program into a larger organization. I am honored to have this paper reprinted in the IRM UK Connects e-newsletter. I hope to meet the publishers at the UK Business Analysts Conference in London this September 24 and 25, 2019.

Great article. For small to medium sized businesses its about resources and knowledge to put things in place. This article provides an excellent infrastructure for a Quality program that is clean and understandable and based on world class methods such as ISO and Baldrige allowing a business to develop the program/system as they themselves grow and develop.